The Hidden Advantages of Choosing Extruded Aluminum Framing Systems

Many industries rely on strong, adaptable materials, but few recognize the full potential of extruded aluminum framing. Beyond its lightweight nature and durability, aluminum framing offers advantages that often go unnoticed. From easier installations to long-term environmental benefits, this system delivers solutions that enhance efficiency and performance in ways most don’t expect.

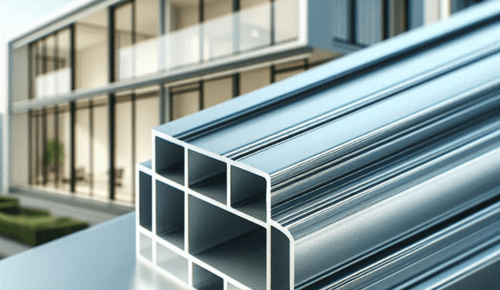

Highly Precise Extrusions Streamline Complex Project Installations

Precision matters in construction and manufacturing, and extruded aluminum framing delivers exact dimensions with every profile. Unlike traditional materials that require extensive cutting and welding, aluminum extrusions come with precise tolerances that ensure seamless assembly. This accuracy reduces the need for modifications during installation, saving valuable time and minimizing project delays.

For projects involving intricate frameworks or modular designs, aluminum framing provides a significant advantage. Each extrusion is engineered for consistency, allowing components to fit together effortlessly without warping or misalignment. Whether used for industrial workstations, automation systems, or structural frameworks, the high precision of extruded aluminum framing simplifies installation while maintaining superior strength.

Intrinsic Thermal Stability That Keeps Structures Consistent Over Time

Extreme temperatures can cause many materials to expand, contract, or degrade, leading to structural instability. Extruded aluminum framing resists these fluctuations, maintaining its shape and integrity even in changing environments. This stability is particularly beneficial in applications exposed to heat, cold, or humidity, where consistency is key to long-term performance.

Unlike steel, which can warp or weaken under thermal stress, aluminum has a lower expansion coefficient, making it an ideal choice for frameworks that require dimensional stability. Over time, this reduces the risk of structural shifts, ensuring that machinery, enclosures, and architectural systems remain secure. With aluminum framing, businesses and builders can count on long-lasting reliability without worrying about seasonal or environmental temperature shifts.

Sustainable Material Properties That Improve Environmental Compliance

Sustainability is becoming a priority across industries, and aluminum framing stands out as an environmentally friendly choice. Aluminum is 100% recyclable without losing its quality, making it one of the most sustainable metals available. Choosing extruded aluminum framing reduces waste and lowers the demand for raw materials, helping businesses meet strict environmental regulations.

Beyond its recyclability, aluminum framing also contributes to energy efficiency. Its lightweight nature reduces transportation emissions, and its natural corrosion resistance eliminates the need for harmful coatings or chemical treatments. Whether used in construction, manufacturing, or renewable energy projects, aluminum framing supports eco-conscious initiatives while maintaining high performance.

Smooth Finishes That Reduce Additional Surface Preparation Costs

Raw materials often require extensive surface treatments before they are ready for use, but extruded aluminum framing comes with a naturally smooth finish. This eliminates the need for costly grinding, sanding, or painting, allowing projects to move forward with minimal preparation. Whether left in its raw state or anodized for enhanced protection, aluminum framing saves both time and money.

In industries where aesthetics matter, such as architecture or retail displays, the clean finish of aluminum framing provides a sleek, modern look without extra processing. The material’s corrosion resistance also means it retains its appearance for years, reducing maintenance costs over time. By choosing extruded aluminum framing, businesses can achieve both functionality and visual appeal without additional expenses.

Non-Magnetic Qualities That Benefit Sensitive Industrial Applications

Certain environments require materials that won’t interfere with electronic equipment or magnetic fields. Extruded aluminum framing is naturally non-magnetic, making it ideal for applications in medical, aerospace, and technology industries. Unlike steel, which can disrupt electromagnetic systems, aluminum ensures that sensitive instruments and machinery operate without interference.

This property is especially valuable in cleanroom environments, where magnetic disturbances can affect precision manufacturing. Laboratories, semiconductor facilities, and MRI rooms benefit from aluminum framing’s ability to provide structural support without generating unwanted magnetic fields. By selecting aluminum framing, industries can maintain the integrity of their operations while meeting specialized requirements.

Integrated Channel Systems Simplifying Future Component Additions

One of the most overlooked advantages of extruded aluminum framing is its built-in adaptability. Many profiles feature integrated channels that allow for quick modifications and additions without the need for welding or drilling. This flexibility makes aluminum framing an excellent choice for evolving projects that may require future adjustments.

For businesses working with automation, shelving systems, or custom enclosures, these integrated channels simplify the process of mounting accessories or repositioning components. Whether expanding a production line or modifying an assembly station, aluminum framing ensures that changes can be made efficiently. This adaptability not only saves time but also reduces costs associated with structural modifications.