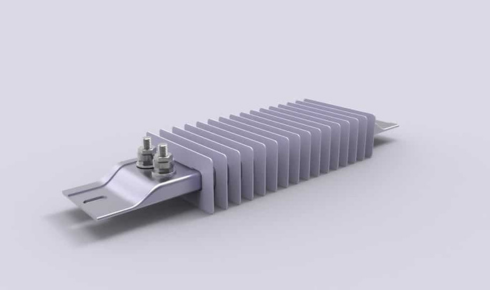

What Are the Benefits of Using Strip Heaters for Flat Metal Heating?

Flat metal components demand steady, controlled heat during fabrication, forming, and processing. Heating them unevenly or too slowly can waste time and damage material quality. Strip heaters offer a focused solution designed specifically for direct surface contact with flat metal.

Provides Quick, Direct Warmth to Flat Metal Surfaces

Strip heaters mount directly against metal surfaces, allowing heat to transfer efficiently from the heater elements into the material. Because they sit flush against the workpiece or die, they do not rely on ambient air to carry warmth. This direct contact speeds up thermal response and reduces the delay between power application and measurable temperature change. Fast heat delivery helps production teams avoid extended warm-up periods. An industrial heater designed in strip form can deliver concentrated energy exactly where it is required. Instead of heating a large chamber or surrounding air, the system focuses on the surface that matters, allowing quicker reaction times and more responsive temperature control.

Helps Reach Target Temperatures with Fewer Heat Losses

Open-air heating systems often lose energy before it reaches the metal surface. Strip heaters minimize this issue because their design encourages efficient conduction. By pressing firmly against a platen or die, heater elements reduce gaps where heat might escape. Reduced heat loss translates into improved efficiency. Less wasted energy means the system can achieve target temperatures without overcompensating. In controlled manufacturing settings, that efficiency can support consistent throughput while lowering operational strain on the equipment.

Even Heat Contact Keeps Metal from Warping Under Stress

Uneven heating can create internal stress within metal. If one section expands faster than another, warping may occur. Strip heaters distribute warmth across their length, maintaining consistent surface temperatures when installed correctly. Uniform heat matters especially in forming and molding applications. Balanced temperature helps the metal expand evenly, reducing distortion. Using an industrial heater that delivers steady contact heat protects dimensional accuracy and minimizes rework caused by deformation.

Reduces Cycle Times in Production with Fast Warm-up

Production lines depend on predictable timing. Slow warm-up periods can delay entire processes. Strip heaters reach operating temperatures quickly, helping reduce the time required between cycles.

Shorter heating phases allow faster transitions from one stage to another. Facilities that rely on repeated heating cycles benefit from heater elements that respond quickly to power adjustments. This responsiveness supports smoother workflows and helps maintain production targets.

Works Well in Tight Spaces Where Broad Heat Is Needed

Compact design allows strip heaters to fit into narrow spaces along flat surfaces. Their slim profile makes them suitable for installations where bulky heating systems would interfere with other components.

Space efficiency does not compromise performance. An industrial heater configured as a strip can provide broad surface heating while occupying minimal room. This adaptability makes it useful in presses, dies, and machinery where layout constraints limit options.

Controls Temperature Without Hot or Cold Spots Forming

Precise temperature control prevents localized overheating. Strip heaters can be wired in zones, allowing operators to manage heat distribution along different sections of a surface.

Consistent output from well-designed heater elements keeps temperatures stable across the metal. That stability reduces the risk of surface imperfections caused by uneven heating. In processes that demand strict tolerances, reliable control can improve final product quality.

Saves Energy by Focusing Heat Only Where It’s Needed

Heating only the required area reduces overall energy consumption. Strip heaters apply heat directly to the target surface instead of warming surrounding structures.

This focused approach makes an industrial heater more efficient. By limiting energy spread, facilities can operate more sustainably while maintaining performance. Concentrated heat application supports both cost control and environmental awareness.

Holds up Under Repeated Heat Cycles Without Failing

Industrial environments often require heaters to cycle on and off throughout the day. Strip heaters are designed to endure repeated expansion and contraction without structural failure.

Durability depends on high-quality heater elements and proper installation. Strong construction allows these units to withstand thermal stress while maintaining output consistency. Over time, dependable performance reduces downtime and maintenance interruptions.

Offers Consistent Performance with Simple Setup Demands

Installation of strip heaters typically involves clamping or bolting them directly to flat surfaces. Their straightforward configuration simplifies setup compared to more complex heating systems.

Once mounted, the industrial heater operates with predictable output. Maintenance remains manageable because components are accessible and easy to inspect. Straightforward design helps operators focus on production rather than troubleshooting.

Reliable flat surface heating requires carefully designed industrial heater assemblies that perform under pressure. The heater elements are constructed for consistent contact heat and durability in repetitive production settings. With tailored builds and knowledgeable guidance, Thermal Corporation supports manufacturers seeking stable and efficient thermal control.