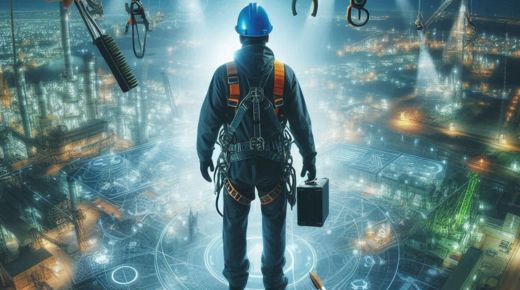

Understanding Fall Protection Harnesses: Essential for Workplace Safety

In industries where employees work at heights, safety is of paramount importance. Fall-related injuries are among the most common and severe in construction, roofing, and other elevated work environments. To minimize the risk of accidents and injuries, employers must ensure that their workers are equipped with appropriate personal protective equipment (PPE). One of the most essential components of PPE in these environments is the Fall Protection Harness.

A fall protection harness is designed to secure workers and prevent them from falling while performing tasks at heights. It plays a critical role in distributing the force of a fall across the worker’s body, reducing the risk of serious injury. However, not all harnesses are created equal, and choosing the right one can make all the difference in safety and comfort.

Key Features of a Fall Protection Harness

A high-quality fall protection harness must meet specific standards to ensure it provides the protection needed to keep workers safe. Some key features to consider include:

- Durable Materials: A harness must be made of strong, durable materials such as nylon or polyester webbing that can withstand the forces generated during a fall. These materials should also be resistant to environmental factors like UV rays, chemicals, and abrasion.

- Adjustability: A proper fit is essential for both safety and comfort. Many harnesses offer multiple adjustment points to accommodate different body sizes and shapes, ensuring a secure and snug fit.

- Padding and Comfort: Comfort is an important factor for workers who need to wear a harness for extended periods. Look for harnesses with padded shoulder, back, and leg straps to reduce pressure and discomfort during use.

- D-Rings: D-rings are metal attachment points located on the harness that connect to the safety lanyard or lifeline. The placement and number of D-rings can vary depending on the harness’s intended use. The most common is a dorsal D-ring on the back, but side and front D-rings may be included for specific tasks.

- Compliance with Safety Standards: Ensuring that your harness meets recognized safety standards is crucial. This brings us to two important safety certifications: ANSI Z359 and OSHA compliance.

ANSI Z359 Harness: A Benchmark for Safety

The ANSI Z359 Harness refers to harnesses that meet the standards established by the American National Standards Institute (ANSI) for fall protection. Specifically, ANSI Z359 is a series of standards related to fall protection systems, addressing the design, performance, and testing of harnesses and other equipment used to protect workers at height.

ANSI Z359 harnesses are designed and tested to meet strict guidelines, ensuring they can handle the forces involved in a fall arrest scenario. When selecting a fall protection harness, it is essential to check for ANSI Z359 certification to ensure it meets these high safety standards. This certification guarantees that the harness will provide reliable protection in hazardous work environments, such as construction sites, scaffolding, and roofing projects.

OSHA Compatible Harness: Meeting Regulatory Requirements

The Occupational Safety and Health Administration (OSHA) sets regulatory standards to ensure workplace safety in the United States. When it comes to fall protection, OSHA mandates that employers provide appropriate safety equipment to their workers. An OSHA Compatible Harness meets the specific requirements set forth by OSHA for fall protection.

OSHA requires that all fall protection equipment, including harnesses, be inspected regularly and maintained in good working condition. A properly rated harness will have clear labeling indicating that it complies with OSHA regulations. This labeling ensures that workers are equipped with the appropriate gear for the tasks they are performing, reducing the risk of accidents and OSHA violations.

Failure to comply with OSHA standards can result in penalties for employers, and more importantly, it can lead to dangerous working conditions. An OSHA-compatible harness is essential for maintaining a safe work environment and ensuring legal compliance.

Comfortable Safety Harness: Balancing Safety and Comfort

While safety is the top priority, a Comfortable Safety Harness can make a significant difference in worker productivity and well-being. Workers who feel comfortable in their safety equipment are more likely to wear it correctly and consistently, reducing the risk of accidents.

Comfort in a fall protection harness comes down to a few key factors:

- Padding: A well-padded harness provides cushioning around the shoulders, waist, and legs, which helps distribute the weight evenly and minimizes chafing.

- Breathability: Many modern harnesses are designed with breathable fabrics and lightweight materials to help reduce heat buildup, especially during long hours in warm environments.

- Flexibility: The ability to move freely while wearing a harness is crucial for workers who need to bend, stretch, and reach during their tasks. A comfortable harness will offer a balance between flexibility and support.

By investing in a comfortable safety harness, employers can improve worker satisfaction and ensure that safety gear is worn correctly throughout the workday.

Roof Safety Harness: Essential for High-Risk Jobs

Roofing is one of the most dangerous jobs in construction, with workers exposed to significant fall hazards. A Roof Safety Harness is specifically designed for roofing tasks, providing workers with the necessary protection when working at height. These harnesses typically feature a dorsal D-ring for secure attachment to a lifeline, ensuring that workers remain connected to a fall arrest system at all times.

Roof safety harnesses must also be durable enough to withstand the harsh conditions often encountered on rooftops, including exposure to the sun, wind, and rain. Additionally, they should provide comfort for workers who spend long hours in precarious positions, often on sloped or uneven surfaces.

Conclusion

Choosing the right fall protection harness is a critical step in ensuring worker safety in high-risk environments. From construction sites to rooftops, a high-quality harness can prevent life-threatening accidents by providing the necessary support and protection. Whether you’re selecting an ANSI Z395 Harness, an OSHA-compatible harness, or a harness designed for comfort, it’s important to prioritize both safety and comfort.

Ultimately, the investment in a durable, compliant, and comfortable fall protection harness is an investment in the well-being and productivity of workers. By adhering to safety standards and selecting the right gear for the job, employers can significantly reduce the risk of falls and create a safer working environment for everyone.

4o