Pilot Plant Equipment: Bridging the Gap from Lab to Full-Scale Production in the Food Industry

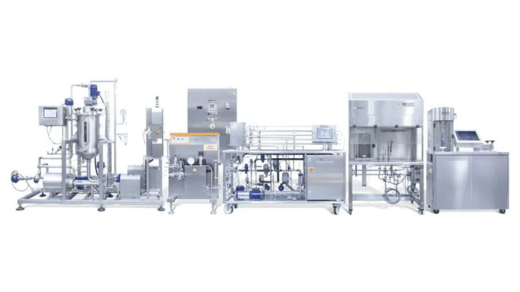

In the dynamic world of food production, the journey from a laboratory concept to full-scale manufacturing involves critical stages of testing, scaling, and refinement. Pilot plant equipment plays a vital role in this transition, serving as a bridge between small-scale experiments and large-scale commercial operations. Armfield, a leader in industrial food technology, provides state-of-the-art pilot plant solutions that prioritize quality, precision, and repeatability.

This guide explores the importance of pilot plant equipment in the food industry, especially within the liquid food sector. We’ll examine different types of equipment, the considerations for selecting the right pilot plant setup, and how these systems are essential for testing and scaling innovative food products.

The Importance of Pilot Plant Equipment in the Food Industry

Pilot plant equipment is essential for developing, testing, and optimizing food products before committing to large-scale production. This equipment allows food technologists and engineers to assess how products behave under production conditions, identify potential issues, and refine processes without the expense and risk associated with full-scale production.

By using pilot plant equipment, manufacturers can:

- Validate Recipes and Processes: Pilot plants replicate production environments on a smaller scale, making it easier to test formulations and production methods.

- Optimize Production Parameters: Manufacturers can test variables such as temperature, pressure, and mixing times, identifying the optimal settings for product consistency, safety, and taste.

- Ensure Compliance with Food Safety Standards: Pilot plants offer a controlled environment to test food safety processes, ensuring compliance with industry regulations before scaling up.

- Reduce Costs and Risks: By identifying issues in the pilot stage, companies can avoid costly errors during full-scale production.

These benefits demonstrate why pilot plant equipment is invaluable to the food industry. In an era of rapid product innovation, having the right pilot plant setup is crucial for companies aiming to stay competitive while maintaining high standards.

Types of Pilot Plant Equipment

Pilot plant equipment varies widely based on the food product being produced, the production process, and the specific requirements of each company. In the liquid food sector, pilot plants often focus on processes like pasteurization, homogenization, filtration, and mixing. Below are some common types of pilot plant equipment used in the liquid food industry:

1. Pasteurization Systems

Pasteurization is a critical process in liquid food production, especially for products like dairy, juices, and sauces. Pilot pasteurization units allow manufacturers to test different temperature and time combinations to ensure microbial safety while preserving flavor and nutritional content. Armfield’s pasteurization systems are designed for precision and control, enabling thorough testing before scaling up to full production.

2. Homogenizers

Homogenization is essential for products that require a stable, uniform consistency, such as milk, cream, and certain sauces. Pilot homogenizers allow manufacturers to assess the impact of pressure and shear force on product texture and stability, ensuring consistency and quality in the final product.

3. Mixing and Blending Systems

Efficient mixing and blending are key in creating homogenous liquid food products. Pilot-scale mixers allow food technologists to test formulations, ingredient compatibility, and blending times on a small scale. This is particularly useful in beverage production, where precise blending is needed to achieve consistent taste and quality.

4. Membrane Filtration Systems

For products that require clarification or concentration, such as juices and dairy-based beverages, membrane filtration systems are invaluable. These systems allow pilot testing of filtration parameters, such as membrane type and filtration rate, ensuring that the full-scale process will yield the desired product characteristics.

Key Considerations for Selecting Pilot Plant Equipment

Choosing the right pilot plant equipment depends on several factors, including the specific application, scalability, and level of control required. Here are a few key considerations:

- Product Compatibility: Select equipment compatible with the types of ingredients and formulations your production process will involve. This ensures the pilot equipment will accurately reflect the conditions of full-scale production.

- Process Control and Repeatability: High-quality pilot plant equipment should offer precise control over variables like temperature, pressure, and flow rate. Armfield’s systems are designed for exceptional control, allowing operators to make adjustments and achieve consistent results with each trial.

- Scalability: It’s crucial to choose pilot plant equipment that can easily scale to full production. Armfield’s solutions are designed with scalability in mind, allowing manufacturers to replicate pilot processes on a larger scale seamlessly.

- Material Quality: Equipment should be made from food-grade materials that are resistant to corrosion, easy to clean, and compliant with hygiene standards. High-quality materials reduce the risk of contamination and enhance the durability of the equipment.

The Role of Pilot Plant Equipment in the Liquid Food Sector

The liquid food sector, encompassing beverages, dairy, soups, and sauces, faces unique challenges in terms of product stability, safety, and consistency. Pilot plant equipment enables manufacturers to overcome these challenges by providing a controlled environment for testing and refining liquid formulations.

In beverage production, for example, pilot equipment allows manufacturers to test flavor stability over time, ensuring that the end product maintains its intended taste profile even after extended storage. For dairy products, pilot pasteurization and homogenization ensure the safety and consistency necessary for consumer trust and satisfaction.

Conclusion

Pilot plant equipment is a vital component of the food industry, particularly in the liquid food sector. By bridging the gap between laboratory experimentation and full-scale production, this equipment allows manufacturers to innovate, refine, and ensure the quality of their products. Armfield’s pilot plant solutions emphasize the importance of high-quality materials, process control, and repeatability, supporting food manufacturers as they bring new and improved products to market.