Filtering Water for Industry: Why Businesses Are Turning to Smarter Solutions

Walk into any factory, brewery, or food-processing plant, and you’ll quickly realize one truth—water isn’t just water. It’s a backbone ingredient, a cleaning tool, a coolant, and sometimes the silent partner that determines whether operations run smoothly or fall apart. Yet, many businesses underestimate just how important clean and reliable water really is until they face scale buildup, machine downtime, or product quality issues. That’s when the conversation around smarter filtration solutions really begins.

The unseen role of filtration in business

It’s easy to take running water for granted. At home, if it tastes fine and looks clear, most people don’t think twice. But for businesses, that same “looks clean enough” mindset can be costly. Even invisible traces of minerals, chlorine, or sediment can affect production lines, sensitive machinery, or even the taste of food and beverages. And let’s be honest—nobody wants to sip on a coffee brewed with metallic-tasting water or buy a product that’s been compromised because of inconsistent filtration.

This is where industrial water filters step in, acting like silent guardians behind the scenes. They aren’t glamorous or something a company brags about in annual reports, but they’re essential. These filters keep unwanted particles, chemicals, and impurities out of the system, ensuring both efficiency and safety.

Commercial-grade needs aren’t one-size-fits-all

A bakery and a hospital don’t face the same water challenges. One is worried about taste and sanitation, the other about sterilization and health standards. Similarly, a microbrewery doesn’t want chlorine messing with yeast fermentation, while a car wash is more concerned with hard water leaving behind mineral streaks on paint.

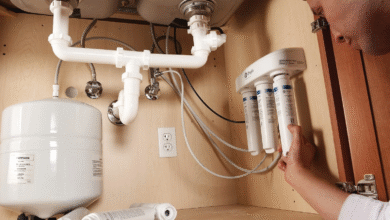

That’s why commercial water filtration systems aren’t cookie-cutter solutions. They’re designed with flexibility in mind, whether that means targeting heavy metals, reducing hardness, or simply improving taste and odor. The systems can scale up or down depending on the size of the operation. For smaller businesses, it might be a compact unit under a counter. For larger facilities, it could mean a complex, multi-stage setup that treats thousands of gallons a day.

When machines drink better, they live longer

Think of water as fuel. If you constantly filled your car with dirty gas, you wouldn’t be shocked when the engine broke down. The same goes for machinery. Boilers, cooling towers, dishwashers, even ice machines—they all rely on water quality. Poor filtration means buildup, corrosion, or blockages, leading to more frequent repairs and higher energy use.

Investing in the right commercial water filter machine isn’t about luxury—it’s about extending the life of equipment and keeping energy costs predictable. Over time, the savings from fewer breakdowns often outweigh the upfront installation expense. It’s like paying for insurance, except instead of paperwork, you get steady performance and peace of mind.

Health, safety, and compliance

For some industries, water isn’t just a utility—it’s a liability if not handled correctly. Healthcare facilities, food producers, and hospitality businesses face strict regulations around water quality. The last thing anyone wants is a contamination incident traced back to a preventable filtration issue. Beyond the legal risks, there’s also public trust. A single misstep can tarnish a brand for years.

Filtration ensures compliance, but more importantly, it reassures customers and employees that safety isn’t being compromised. In a world where consumers are increasingly curious about how products are made, businesses can’t afford to cut corners. Clean water is a baseline expectation, not a luxury feature.

Sustainability and smart water use

Modern filtration isn’t just about blocking impurities. It’s about smarter, more sustainable water use. Many businesses are under pressure to reduce waste and cut down on their environmental footprint. Advanced filters can help recycle water within facilities, minimize chemical usage, and reduce overall demand on municipal supplies.

There’s also an energy angle. Cleaner water means equipment runs more efficiently, consuming less power. For companies juggling both profit margins and sustainability goals, filtration can quietly support both sides of the equation. It’s not flashy, but it’s measurable.

The real-world impact on products and people

Take the beverage industry as a clear example. Coffee chains, breweries, and bottled water brands live or die by taste consistency. Tiny variations in mineral content can drastically alter flavor. In this world, water filtration isn’t just maintenance—it’s brand protection.

Even in sectors where water isn’t consumed directly, like textiles or electronics, filtration affects the outcome. Fabrics washed in hard water may not hold dye properly. Electronics assembled with contaminated rinse water risk higher defect rates. The ripple effects can be huge, reaching all the way to the customer’s hands.

Choosing the right system

This is where businesses often hesitate. The market is full of options—reverse osmosis, activated carbon, UV purification, multi-stage systems. The “right” choice depends on source water, budget, industry requirements, and long-term goals. It’s rarely a one-and-done decision.

Smart companies usually begin with a professional water analysis. From there, they can match the system to actual needs rather than guesswork. Cutting corners at this stage often leads to disappointment later. It’s a bit like tailoring a suit—sure, you can buy off the rack, but nothing beats a fit that’s measured just for you.

The cost conversation

Yes, upfront costs can sting. Filters, machines, installation—it adds up quickly. But the question isn’t just “How much will it cost?” It’s “How much will it save me over time?” Avoided repairs, energy efficiency, extended equipment life, better product quality, and compliance peace of mind—all those factors tilt the math in filtration’s favor.

For many businesses, the ROI comes faster than expected. And beyond money, there’s also the intangible benefit of fewer headaches, smoother operations, and less time spent fighting preventable problems.

Final thoughts: the quiet foundation of business success

Water doesn’t get the same attention as marketing strategies, product launches, or financial forecasts. Yet, it’s often the invisible foundation holding everything together. A single bad water day in a factory can halt production, spoil product batches, or damage equipment in ways that ripple far beyond the utility bill.

Industrial and commercial water filtration isn’t glamorous. It won’t make headlines or win awards. But it does something more important—it keeps businesses reliable, efficient, and trusted. And in a competitive world, that quiet dependability can be the difference between thriving and constantly playing catch-up.